Energy-efficient... Indestructable... Reconfigurable...

The world’s most advanced low voltage LED-based temporary lighting system for construction sites. Explore our Modules:

THE FM2A

Replaces traditional temporary string lights (100W A-lamps)

6W/1000 lumen | Spacing: 10-15 feet

THE FM10A

Use in place of cumbersome, dangerous low-bay lighting.

30W/3000 lumen | Spacing: 15-25 feet

THE FM30A

Safer and more efficient than traditional high-bay lighting.

60W/6000 lumen | Spacing: 25-40 feet

FLEX SLS Lighting Systems are incredibly easy to install AND remove from job site to job site. Get years of use out of one efficient system. No more cutting cheap, dangerous lighting out of the walls and throwing money in the dumpster.

For Immediate Assistance, Call 516-967-2981

An Energy-Efficient, Maintenance-Free Alternative to CFL, HID, and Line Voltage LED Systems

Clear-Vu Lighting’s award-winning FLEX SLS Site Lighting System is safer, more energy efficient, cost-effective, and flexible than traditional line voltage temporary lighting systems including incandescent/compact fluorescent/LED lamp-based “stringers” and 400W metal halide fixtures or their fluorescent equivalents for a wide variety of applications. FLEX LED modules are IP66-rated, extremely rugged and durable (can withstand 15’ drop test) and theft-resistant due to the proprietary T-Connectors. And now, with the Intelligent Control System, an entire jobsite’s temporary lighting can serve as an emergency alarm—controlled and managed from a single access point!

The FLEX SLS Site Lighting System includes three standard modules designed to simplify layouts in 10/20/30 foot spacing. All the modules can be co-mingled on the same 24VDC low-voltage bus line, and are backwards compatible with the previous generations of the FLEX System:

THE FM2A | 6W/1000 lumens

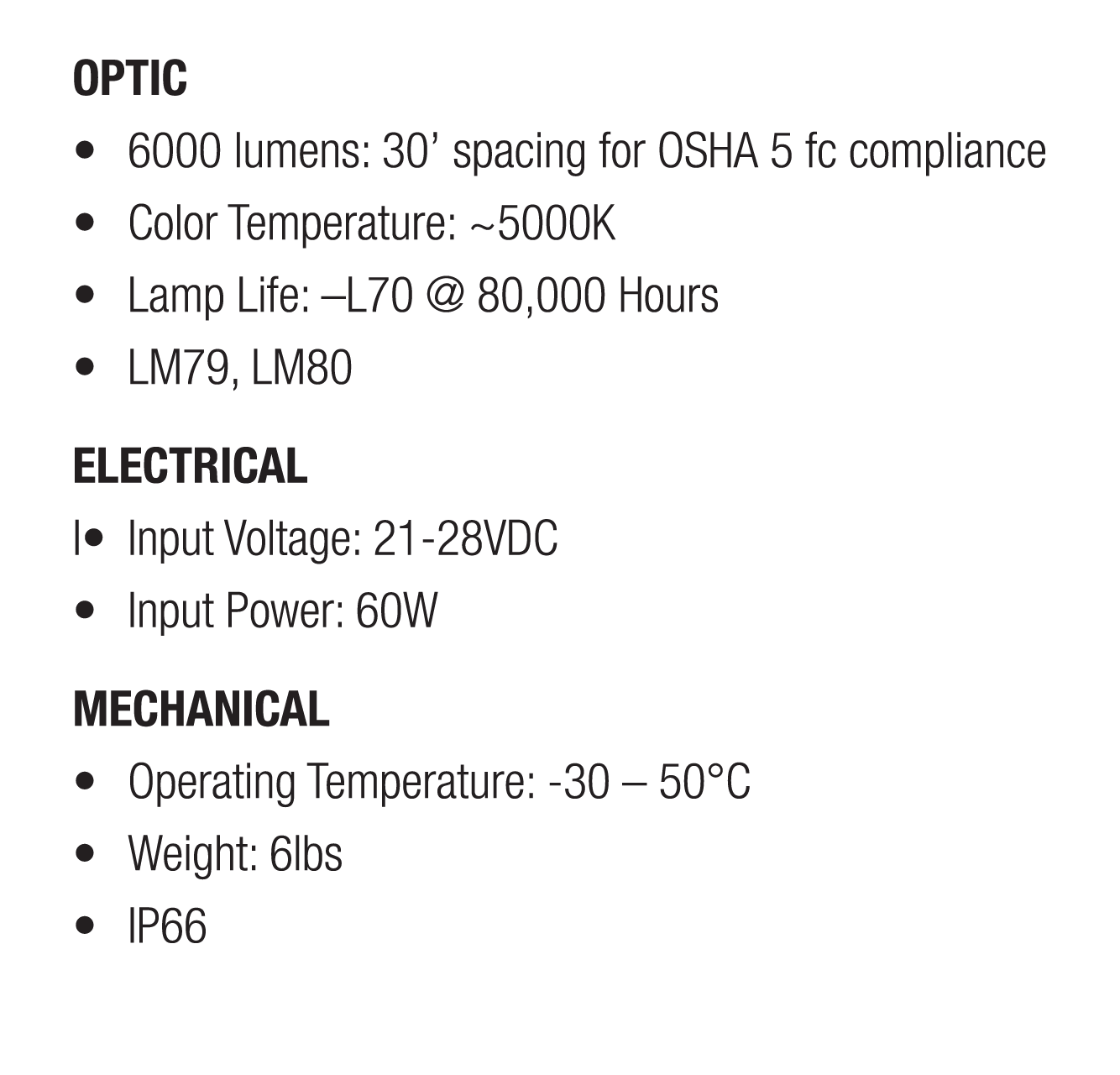

DIMENSIONS & SPECIFICATIONS

The FM2A module produces 5-foot-candles (average) at 10-12 foot spacing. The directed optics provide up to 30% more light on the ground than a 27W CFL lamp. Ideal for fit-outs of smaller rooms.

INSTALLATION CONFIGURATIONS

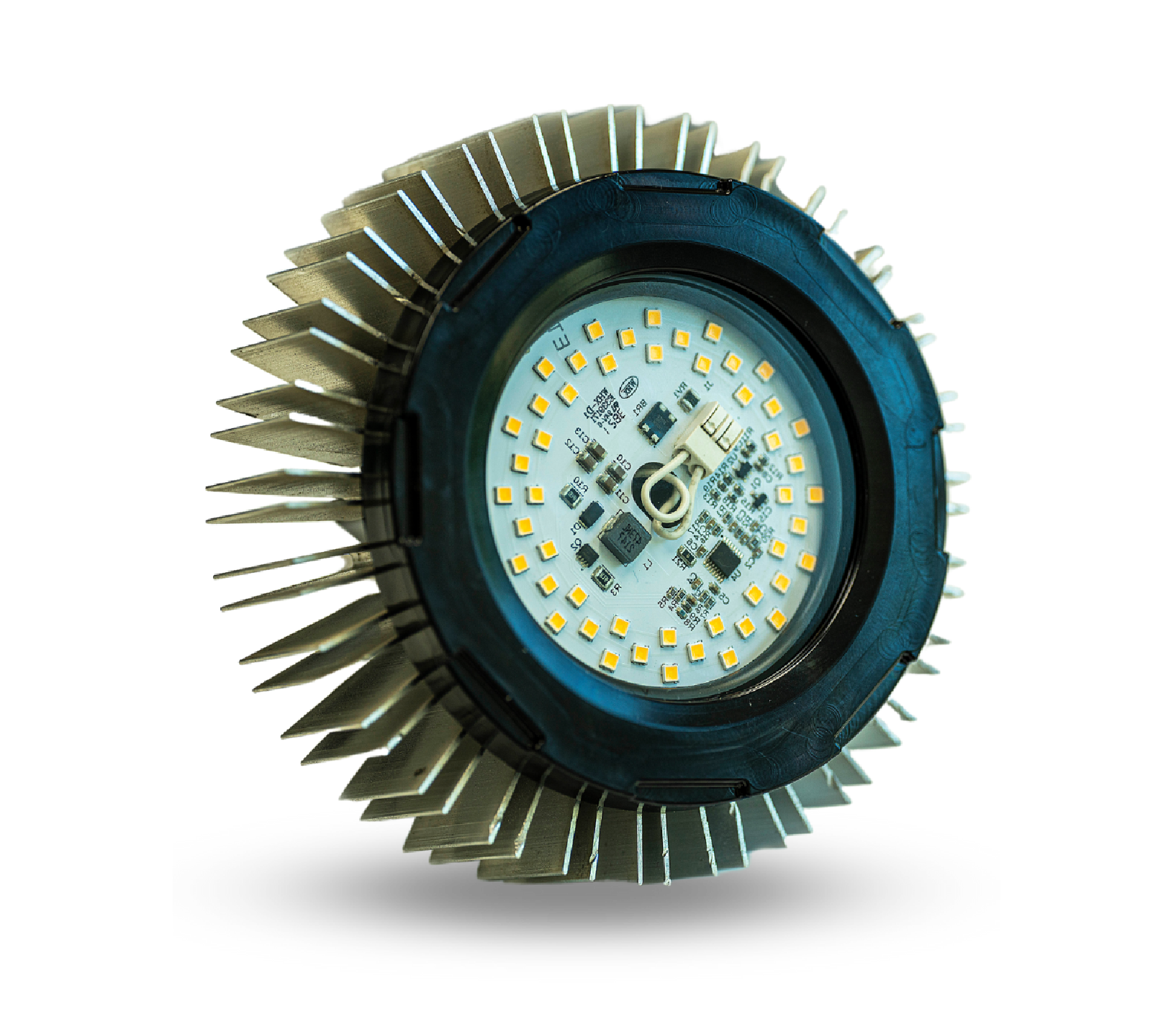

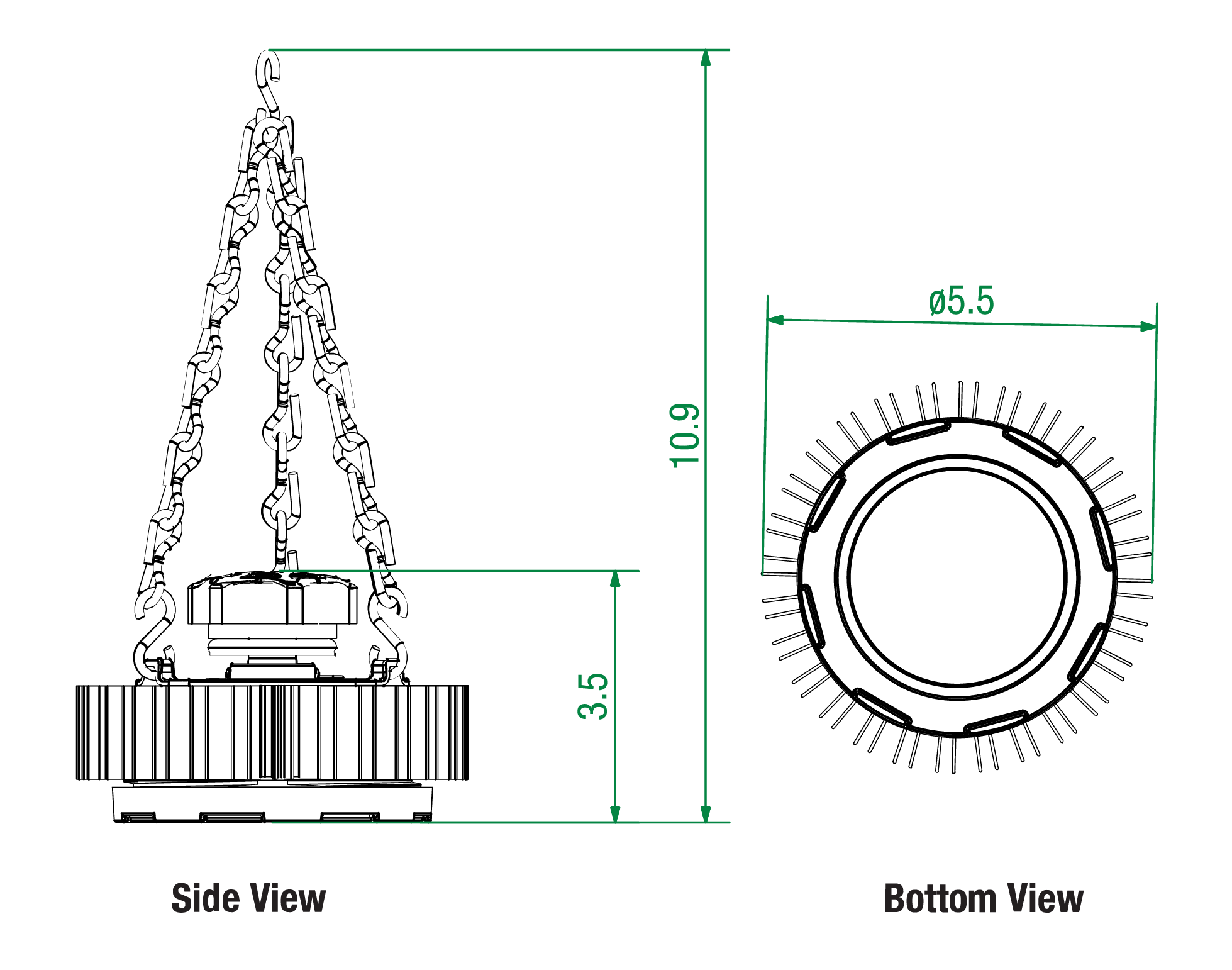

THE FM10A | 30W/3000 lumens

DIMENSIONS & SPECIFICATIONS

The FM10A module produces 5-foot-candles (average) at 20 foot spacing. Ideal for special applications requiring 20 foot spacing and/or surface mount (i.e. tunnels).

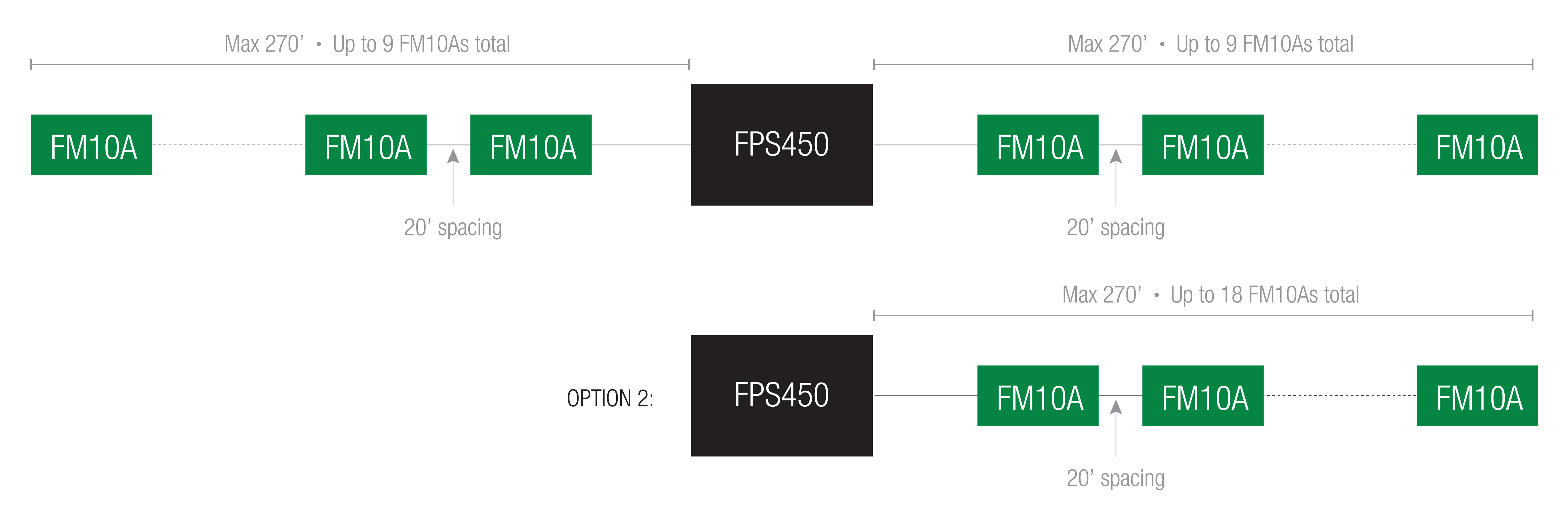

INSTALLATION CONFIGURATIONS

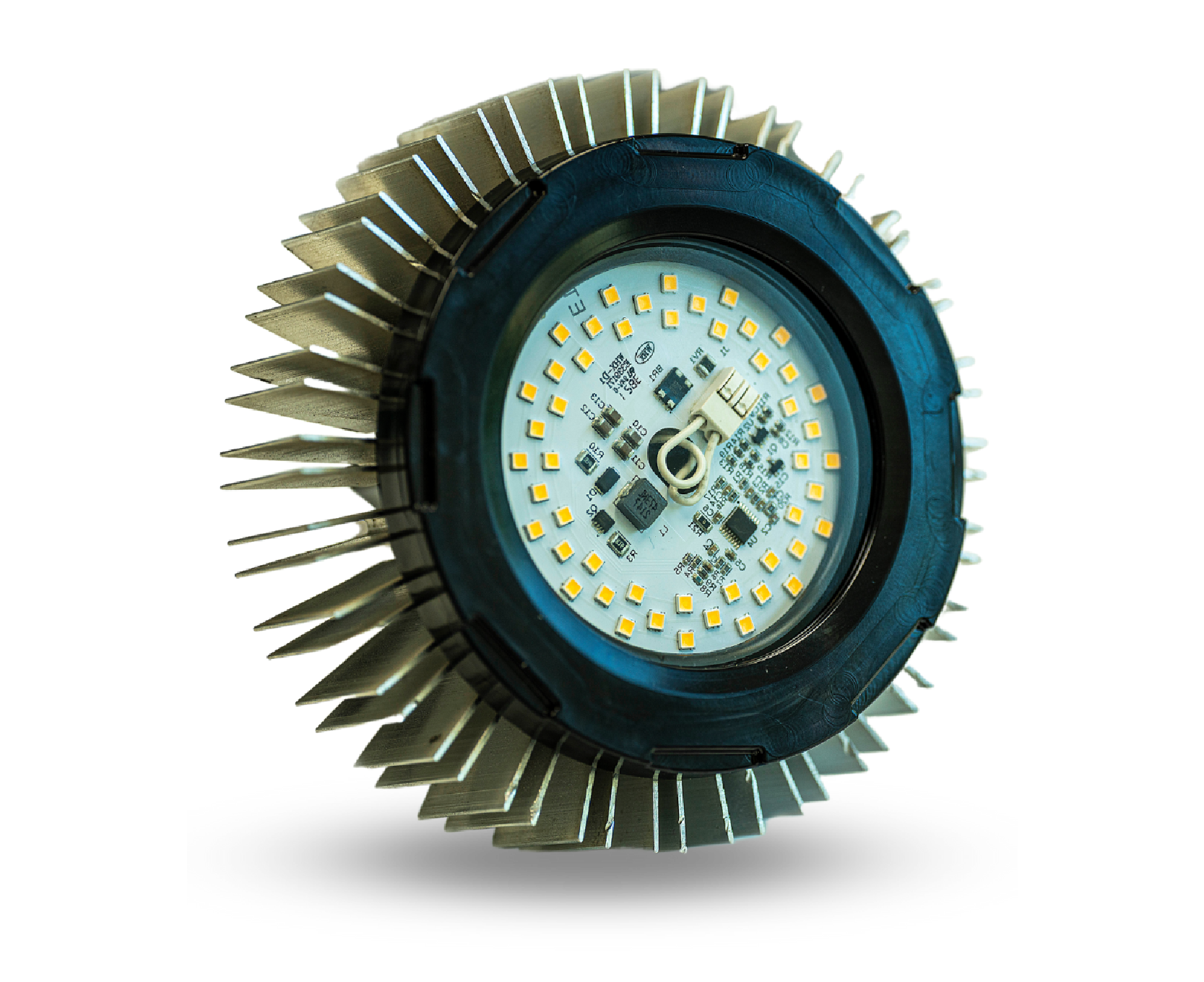

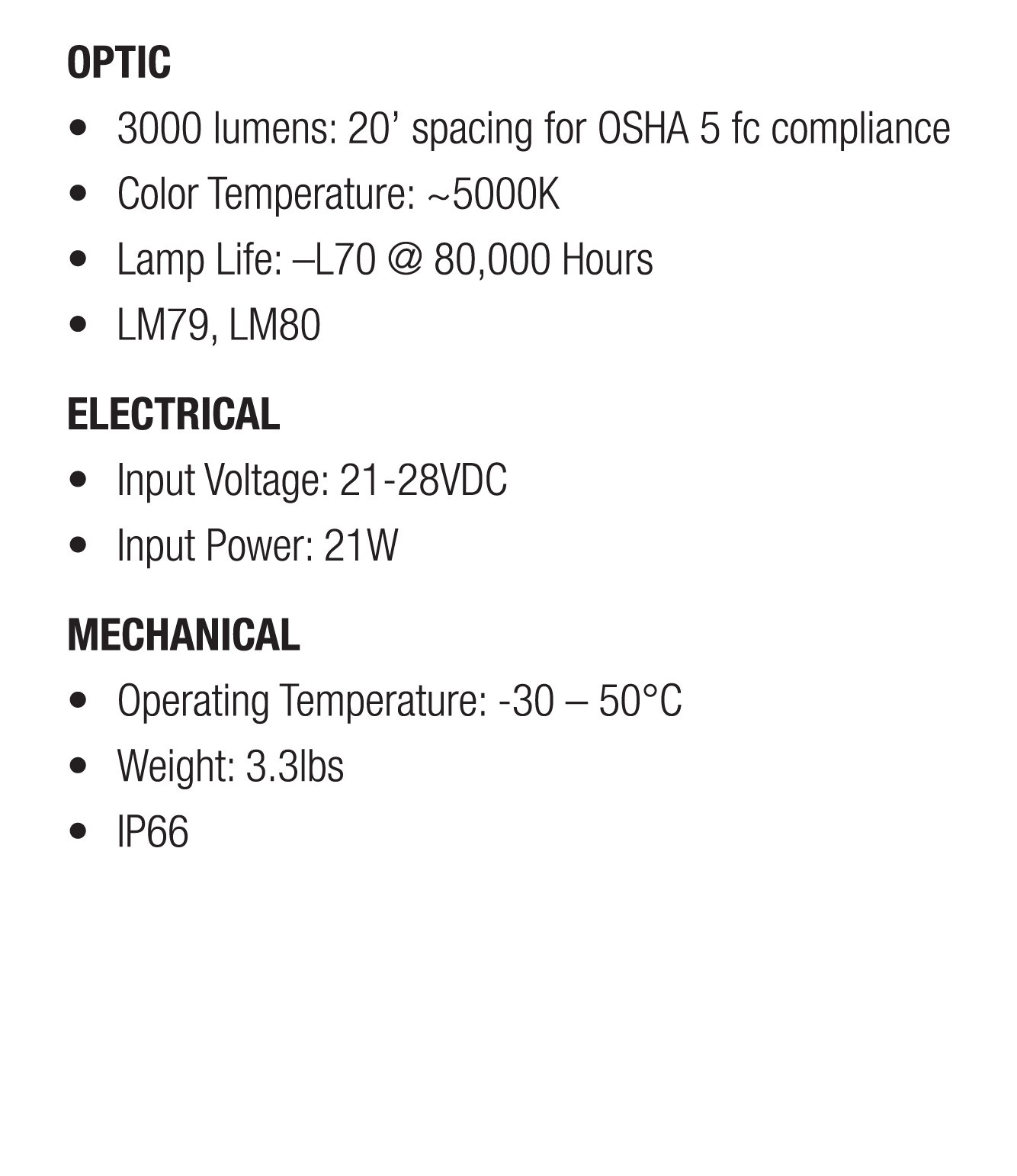

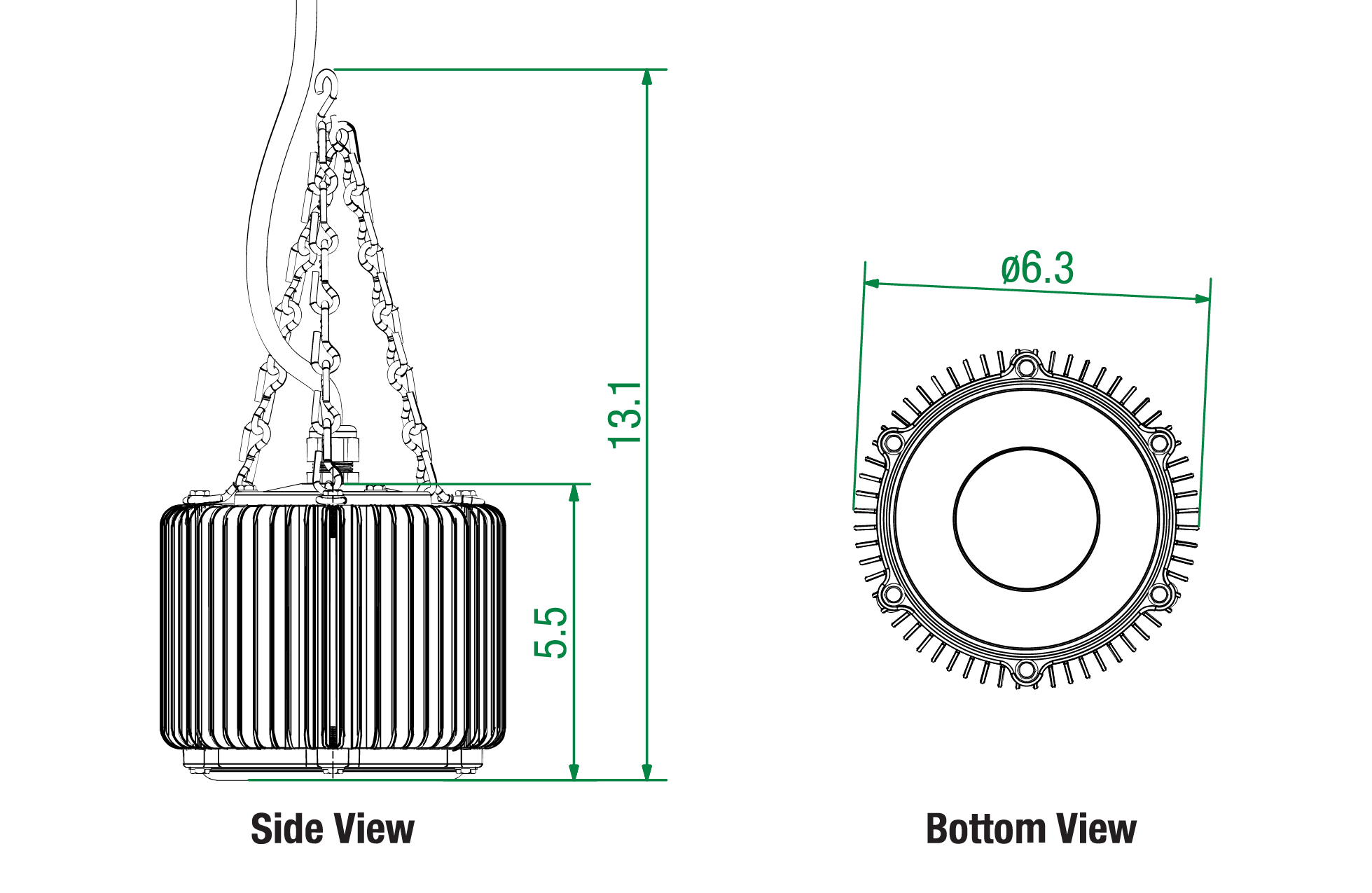

THE FM30A | 60W/6000 lumens

DIMENSIONS & SPECIFICATIONS

The FM30A module produces 5-foot-candles (average) at 30 foot spacing and has an integral uplight, eliminating the cavern effect in projects with high ceilings above 12 foot. Ideal replacement for traditional 400W metal halide and high-output fluorescent fixtures.

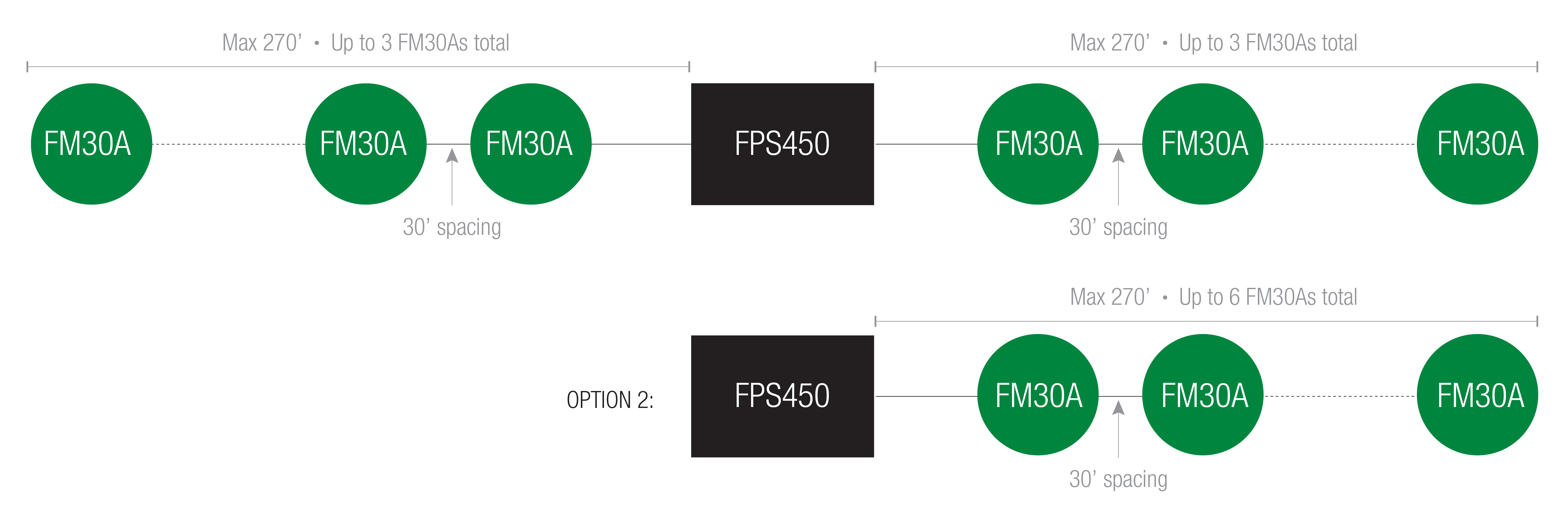

INSTALLATION CONFIGURATIONS

The FLEX SLS Site Lighting System even allows you to mix and match your installation to fit ANY WORK ENVIRONMENT!

Read about our accessories & full system details below:

-

T-connector

An injection-molded nut and twist-base assembly that houses piercing teeth. When the bus line is fed into and secured to the connector, an over-molded rubber channel creates an IP66 seal between the LED module and bus line. No more splices required.

An injection-molded nut and twist-base assembly that houses piercing teeth. When the bus line is fed into and secured to the connector, an over-molded rubber channel creates an IP66 seal between the LED module and bus line. No more splices required. -

Power supplies

FPS450

On/Off power supply. A 450W supply that accepts a 95-265VAC input and outputs at 24VDC to energize up to 6 FM30A, 18 FM10A or 54 FM2A modules, or a combination of the three.

FPS450DT

Optional time clock and dimmer power supply. A dimmer and programmable time clock enables an additional 75% reduction in power consumption during off-hours (night mode) while providing 1-2 fc module output for emergency egress applications.

FPS450I

Optional intelligent control power supply. Integrates a wireless mesh network transceiver and relay into each power supply enabling remote programming of light levels on a weekly schedule, as well as an emergency alarm function. -

FIS1: Intelligent control system

FIS1

Project-wide control from single access point. Save energy and create safe lighting conditions with project-wide control of temporary low-voltage LED construction site lighting from a single access point. Operate at full, low, or off power, and alarm mode for emergencies. Optimal lighting conditions are easy to program, manage and reconfigure. -

Accessories

Concrete Deck Box – Makes installations faster and easier to install, maintain, and remove. Low voltage bus line can be integrated into the deck – leaving it out of harm’s way. Modules are simply removed, and all evidence of temporary boxes vanish behind a skim-coat.

Make the smart choice and get it done right!

- Want safe and sustainable construction site lighting?

- Want a system that is easy to install and reconfigure on a dynamic job site without getting buried in the walls?

- Want long-life LEDs and robust construction that minimizes maintenance costs and encourages reuse?

- Want higher levels of illumination while reducing energy costs by 80+%?

- Want different types of temporary lighting for general area, access areas, back of building, stairwells, and path of egress?

- Want to eliminate OSHA inspector violations due to bad splices?

FLEX SLS Works for the entire construction value chain

- Developers/Building Owners

- Architects/Electrical Engineers/Lighting Designers

- Construction Managers/General Contractors

- Electrical Contractors

- Distributors

If you need temporary lighting, you need FLEX SLS.

what makes

FLEX SLS unique?

safe & secure

- The power distribution system is entirely low voltage – eliminating the risk of electrocution and shock hazards on jobsites.

- LED modules are never too hot to touch and substantially reduce the possibility of injuries and fires.

- LED modules conform to OSHA foot candle requirements.

- Your entire temporary lighting installation can serve as an emergency alarm for building evacuation.

cost-effective & sustainable

- FLEX SLS consumes less than 1/4 the energy compared to existing lighting technologies.

- FLEX SLS earned a LEED ID Credit due to the significant decrease in electricity consumption and electrical waste.

- RoHS compliant

- Contains no hazardous materials

installation & labor efficient

- LED modules have twist and lock connectors for ease of installation.

- Allows unlimited spacing of stringers and hardwiring of fixtures for optimal spacing

- All LED modules can be co-mingled on the same 24VDC low-voltage bus line.

durable

- Impact resistant and impervious to environment – IP66-rated module enclosure designed to withstand extreme environmental and physical abuse.

- IP66-rated.

- Power supply includes secondary surge protection for lighting strikes.

- Will survive a 15’ drop test on concrete.

Everything you need to know about FLEX SLS

FLEX SLS’s system overview, installation configurations, sample lighting layouts, accessories, specifications, and ROI and a project savings calculator at your fingertips. Download BrochureRead what Our FLEX SLS Customers say...FLEX SLS LIGHITNG SYSTEMS ARE EASY TO USE...

"We were actually putting up conventional lighting, and we stopped. It's tremendous ...the guys love these things because of the simplicity of installation - and no maintenance."

- Paul D, Skanska USA

FLEX SLS LIGHITNG SYSTEMS ARE SAFE & EFFICIENT...

“From a safety aspect, the FLEX System’s low voltage operation has mitigated the electrocution hazard during material handling. The system provides excellent illumination, is time efficient to install and modify, and maintenance is minimal as it can endure a great deal of abuse while continuing to function. I would look forward to using FLEX on my next project, it is superior to traditional temporary lighting.”

– James P, Turner Construction Co

FLEX SLS LIGHITNG SYSTEMS WILL LAST FROM JOB TO JOB...

“Without the FLEX SLS Lighting System’s robust construction that was able to withstand our ‘durability test,’ the 50,000 hour life of a typical LED bulb would have been of little value.”

– Brian S, Benchmark Builders

FLEX SLS LIGHITNG SYSTEMS CREATE A SUSTAINABLE WORKPLACE...

“After Clear-Vu Lighting’s FLEX SLS lighting system was installed, I walked through the construction site and saw high levels of uniform lighting with no dark corners. The University of Washington is creating a safe working environment with dramatically lower energy costs and that is an excellent example of true sustainability.”

– Mindy U, Skanska, NW Regional Safety Director

Contact Us to Place Your Order!

Find out how to save on temporary lighting for your next construction project.

For Immediate Assistance, Call 516-967-2981