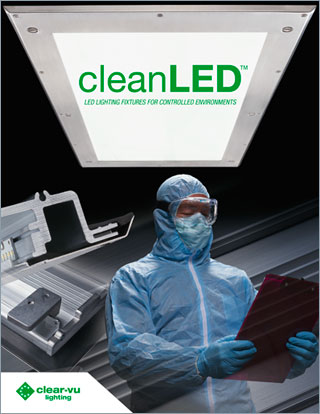

Lighting Fixtures Designed, Manufactured, and Tested to the Demanding Requirements for Cleanroom/Controlled Environment Projects

The first true cleanroom fixture designed for LED

MEETS ALL ENVIRONMENTAL CHALLENGES

- Extruded aluminum housing is the heat sink

- Walkable fixture supports 1,000lbs and is only 2" deep

- No surface welds = no rust from Spor-Klenz or other cleaning protocols

- Edgelit optic creates a uniform, ultra-wide illumination pattern with no hot spots or shadows

cleanLED’s edge-lit optical system eliminates direct glare and minimizes shadows. It is our Energy-Efficient, Maintenance-Free Alternative to CFL, HID, and Line Voltage LED Systems.

THE LENS FRAME

The stainless steel lens frame corners are die-formed and trimmed rather than notched and seam welded. Eliminating welded corners avoids destroying the chromium content and compromising the corrosion resistance of the stainless steel. Additionally, the lens frames fasteners close proximity to the lens frame perimeter avoids cantilevering and promotes ceiling contact.

IMPACT RESISTANT LENS

The clear impact-resistant lens is NSF silicone sealed and securely held in place with continuous lens retention brackets with mitered corners.

THE GASKET

The patented one-piece injection molded closed cell silicone gasket provides a consistent custom fit between the ceiling/housing fl ange/ lens frame, eliminates potential failure of vulcanized corners, and produces maximum seal with minimum compression.

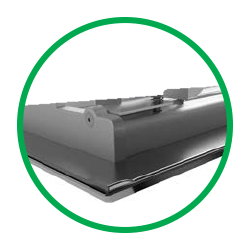

THE LOW-PROFILE HOUSING

The low-profile housing (less than 2.0”) with patented swing-out arm installation mechanism allows universal installation in traditional gypsum, 2.0” walkable ceiling panels and 2.0” T-bar grid ceiling systems without opening the fi xture – dramatically reducing installation costs. This cleanLED housing (less than 2.0”) is also designed to maximize thermal conductivity of heat away from the junction points of the LEDs. Three factors impact the effectiveness of the thermal conductivity – material, mass and surface area. The choice of aluminum over CRS increases thermal conductivity at least 300%. In order to maximize mass the housing is extruded with thicknesses greater than .20” compared to .048” thickness of 18-gauge CRS. Adding fins to the extrusion profile le increases the surface area by 70% over 18-gauge CRS.

cleanLED is IP66 rated to assure that pathogens and particulates will not enter or pass through the lighting fi xture. IP66 is the highest level of dust and moisture protection without entering the categories for submersible lighting fi xtures.

NSF2/Splash Zone is a listing that addresses materials, design and construction as it relates to ease of cleanability, corrosion resistance and toxicity. cleanLED is constructed from stainless steel and aluminum and is impervious to corrosion. The enclosure has been designed to produce a progressive surface with the ceiling structure to promote ease of cleanability. The construction of the enclosure is robust and will withstand the most aggressive cleaning protocols.

Electronic equipment in controlled environments must be protected from radiated and conducted emissions that might compromise the patient, surgical procedures and imaging operations. “Military Standard 461F-Air Force/Navy Fixed” testing procedures provide tangible proof that cleanLED will operate within ranges (RE and CE) that are safe for controlled environments.

cleanLED 2x4 luminaires are Design Lights Consortium Qualifi ed - DLC qualifi ed. DLC qualifi ed is a prerequisite for most utility rebate programs. According to DLC, “When you purchase a product with DLC certification you can rest assured that you’ve chosen a highly scrutinized product that has been produced to some of the highest industry standards for quality and effi ciency.”

Everything you need to know about cleanLED

cleanLED product overview, specifications, and dimensional data at your fingertips.

Get a Quote

Find out how to Control LED performance on your next controlled environment project.